Classification

Contact Us

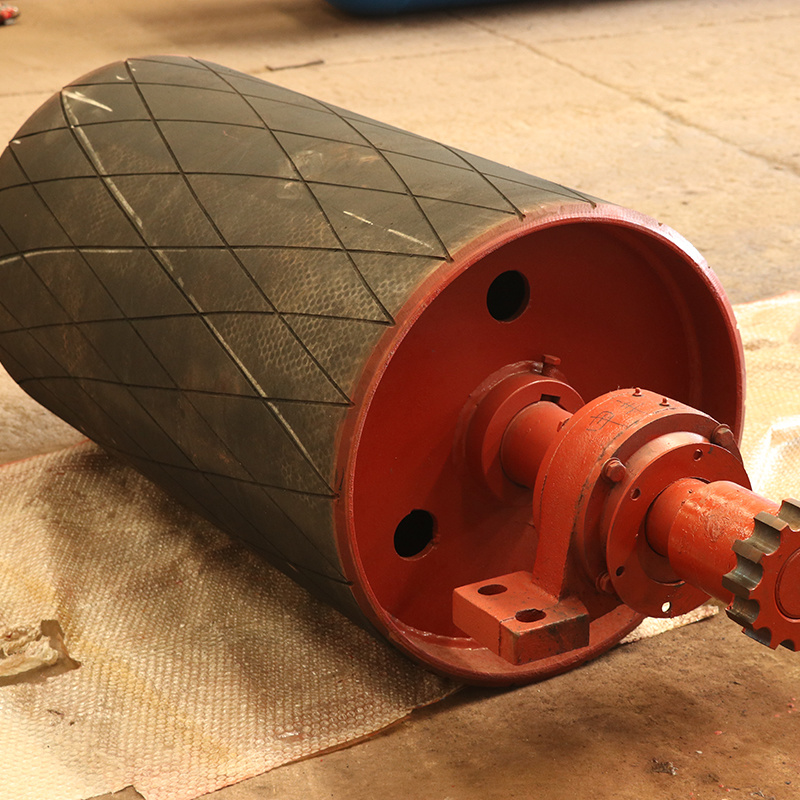

Drive Roller

Key words:

Classification:

Product Details

Drive drum, also known as the drive pulley, is the "heart" and power source of the belt conveyor system. Its main function is to convert the torque and rotational motion transmitted from the motor and reducer into continuous and stable traction force for the conveyor belt through the friction between the drum surface and the belt, thereby driving the entire conveyor system and materials forward.

Hebei Xinyuan, as a professional conveyor machinery manufacturer, produces drive drums that are precisely designed and manufactured, featuring high torque transmission, smooth operation, long service life, and safety and reliability. They are the core components ensuring efficient and reliable operation of conveyors.

Product Introduction

The drive drum usually consists of the following main parts:

· Shell (casing): The main body of the drum, usually made by rolling and welding high-quality carbon steel (such as Q235B, Q345B), with sufficient thickness and rigidity to withstand large torque and radial loads. The surface can undergo various treatments (see below) to increase the friction coefficient.

· Shaft: Made of high-strength alloy steel (such as 40Cr, quenched and tempered 45 steel), it is the core part for transmitting torque and bearing bending moments. Its diameter and structure are strictly calculated to ensure sufficient torsional and bending strength.

· Spokes (hub): The key component connecting the shell and the shaft, effectively distributing the torque transmitted by the shaft across the entire shell. Usually adopts welded structure (spokes welded to the shaft) or shrink-fit connection.

· Bearing housing: Built-in high-quality self-aligning roller bearings, used to support the entire drum assembly, ensuring flexible and smooth rotation.

Main Application Areas

As the power source, the drive drum is used in almost all types of belt conveyors, spanning various industries:

· Mining: Long-distance, large-capacity heavy-duty conveyors for underground and open-pit mining of coal, metal ores, limestone, etc.

· Ports and docks: Ship loaders, ship unloaders, stackers and reclaimers, and their rear conveyor systems, requiring high reliability and efficiency.

· Thermal power plants: Coal conveying systems from coal yards to boiler rooms.

· Steel metallurgy: High-temperature, heavy-load material conveying lines in raw material yards, sintering, ironmaking, and steelmaking workshops.

· Cement manufacturing: Full-process conveying equipment from raw material crushing to finished cement dispatch.

· Chemical and grain processing: Conveying of various bulk materials.

Product Design

The design of Xinyuan drive drums covers materials science, structural mechanics, and transmission theory. Core design points include:

1. Structural forms:

· Single plate welding: Suitable for medium and small power, narrow bandwidth drums.

· Double plate welding: The most commonly used structure, good rigidity, suitable for most working conditions.

· Triple plate welding: Suitable for ultra-high power, ultra-wide bandwidth heavy-duty drums, ensuring shell rigidity and uniform torque transmission.

· Key connection vs. shrink-fit connection: Traditionally uses key connection; modern designs increasingly adopt shrink-fit connection, which requires no keyway, avoids stress concentration, is easy to assemble and disassemble, and has good alignment.

2. Surface treatment (rubber coating): To significantly increase the friction coefficient, prevent slipping, and protect the conveyor belt, the drum surface must be treated.

· Smooth rubber: Suitable for low power, dry environments.

· Chevron groove rubber: The most commonly used, with good drainage and mud discharge capabilities, high friction coefficient, directional to help alignment and prevent deviation.

· Diamond (rhombic) groove rubber: Excellent friction performance, non-directional, suitable for reversible conveyors.

· Ceramic rubber surface: Ceramic pieces embedded in rubber, extremely high friction coefficient, especially suitable for wet, high-traction demanding harsh environments (such as elevators, long-distance large-angle conveyors).

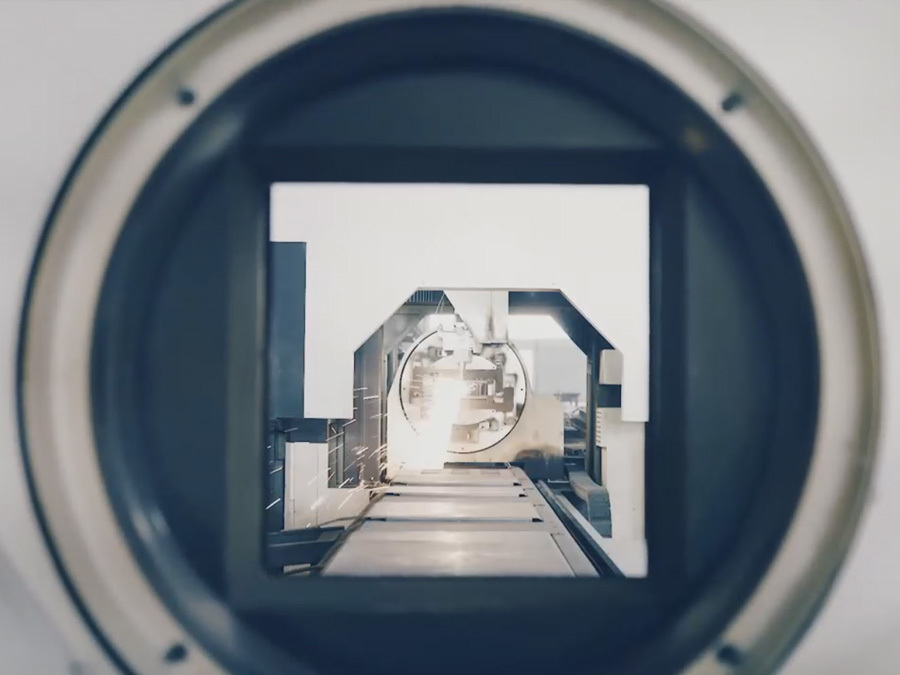

3. Balancing and processing: The drum must undergo dynamic balance correction before leaving the factory to ensure low vibration and noise during high-speed operation, protecting bearings and conveyor belts.

Conveyor Belt Matching Design Features

The coordination between the drive drum and conveyor belt is dynamic and critical:

· Wrap angle: The angle corresponding to the arc length of contact between the conveyor belt and the drum. Increasing the wrap angle (e.g., using dual drives or increasing the angle of the redirecting drum) is an effective way to improve traction.

· Conveyor belt tension: The conveyor belt must maintain sufficient tension, which is a prerequisite for generating frictional traction. Insufficient tension will cause drum slippage, severe rubber surface wear, or even conveyor belt burning.

· Joint method: The vulcanized joint of the conveyor belt must be smooth and strong to avoid impact and additional stress when passing over the drum.

Features and Advantages

1. High load and high torque: Using optimized structural design and high-quality materials to ensure the transmission of huge driving torque, meeting the needs of heavy load start-up and operation.

2. Excellent traction performance: Multiple rubber coating types available, providing the best friction coefficient, effectively preventing drive slippage and ensuring conveying efficiency.

3. Smooth and reliable operation: Precision machining and strict dynamic balance testing ensure low vibration, low noise, smooth operation, and extended bearing and conveyor belt life.

4. Long Service Life: The wear-resistant rubber coating protects the cylinder from abrasion, and the high-quality bearings and excellent sealing structure greatly extend the maintenance cycle and service life.

5. Safe and Reliable: Robust design and manufacturing quality prevent serious accidents such as shaft breakage and cylinder cracking, ensuring the safety of the entire production line.

6. Easy Maintenance: The use of standardized bearings and expansion sleeves makes later maintenance and part replacement more convenient and faster.

Company Introduction

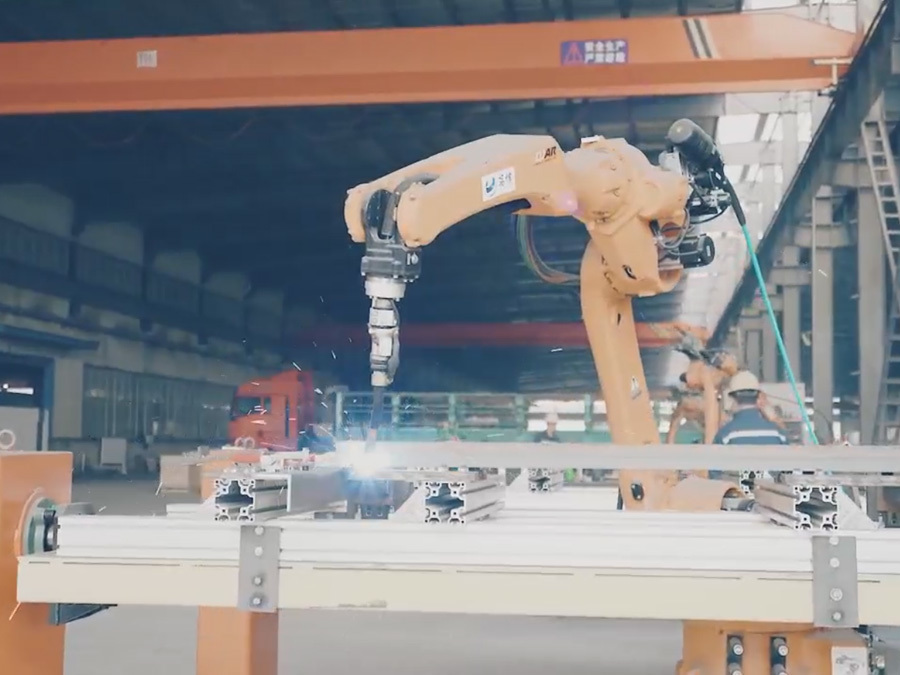

Hebei Xinyuan Conveying Machinery Co., Ltd. covers an area of 260 acres, with a large scale and 560 outstanding employees. They work together to create a brilliant performance with a 0.26 billion annual output value. The company is committed to the research and development, production and sales of belt conveyor, steel structure, glass fiber reinforced plastic and other products. The products are widely used in mining, port, electric power, chemical industry, building materials and other industries, and are deeply trusted and praised by customers.

Our advantage

The company is committed to the research and development, production and sales of belt conveyor, steel structure, glass fiber reinforced plastic and other products. The products are widely used in mining, port, electric power, chemical industry, building materials and other industries, and are deeply trusted and praised by customers.

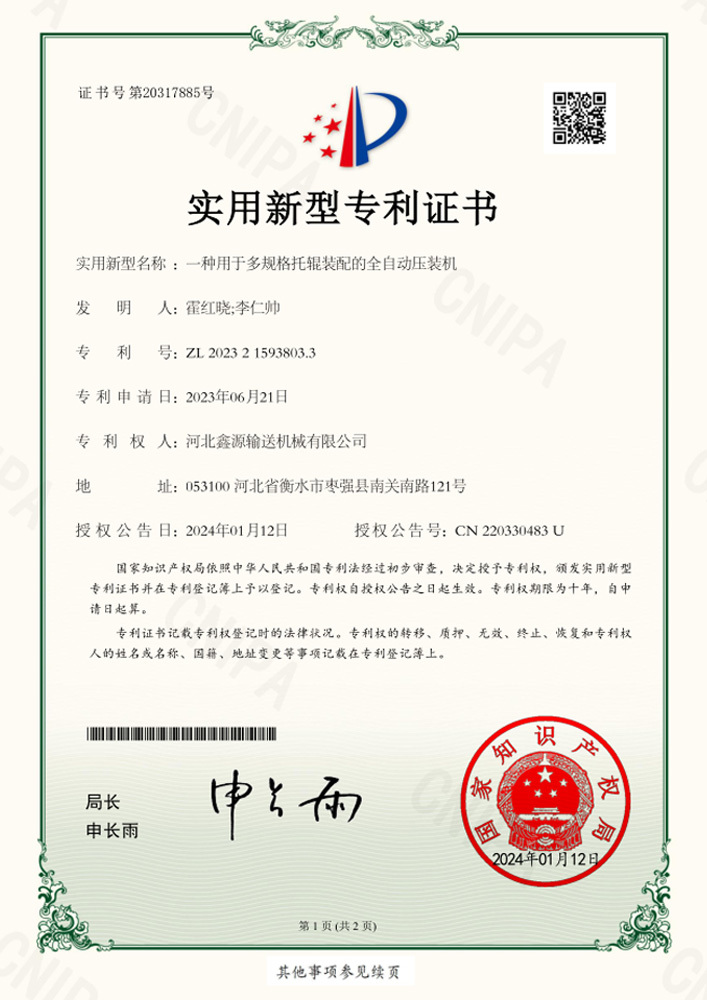

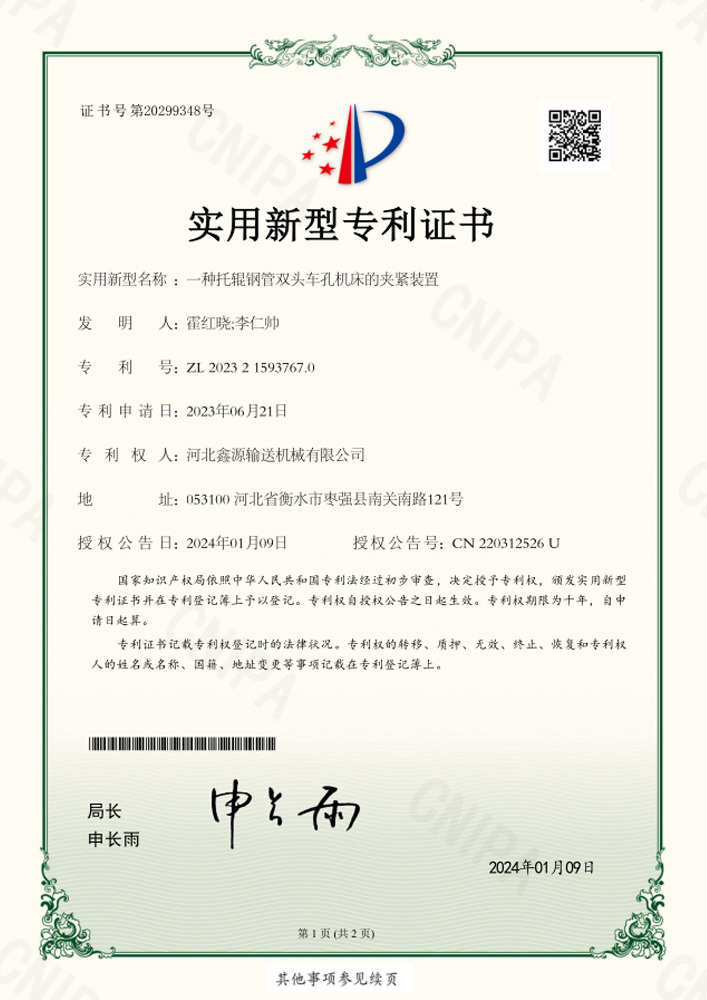

Industry experience

Since its establishment in 2003, the company has more than 20 years of conveyor production and operation, has a professional after-sales service team, and has 18 utility model patents.

advanced equipment

The use of advanced manufacturing technology, with a variety of testing equipment, to ensure that each product is in line with national standards and customer requirements.

Marketing Network

We have established long-term and stable cooperative relations with many domestic enterprises, and exported to overseas countries and regions such as the Middle East, Central Asia and Southeast Asia.

Qualification and Exhibition

Contact Us

Hebei Xinyuan Conveying Machinery Co., Ltd.

We are dedicated to providing customers with quality products and professional services,

Welcome you to come to discuss, we are willing to work together to create a better tomorrow!

Landline:

Mobile:

Mailbox:

Address:

Company address: east side of Dongwai Ring Road, Zaoqiang County, Hengshui City, Hebei Province

Previous Page:

Next page:

Product inquiry

* Please leave your phone number and we will contact you within 24 hours!

Related Products