Classification

Contact Us

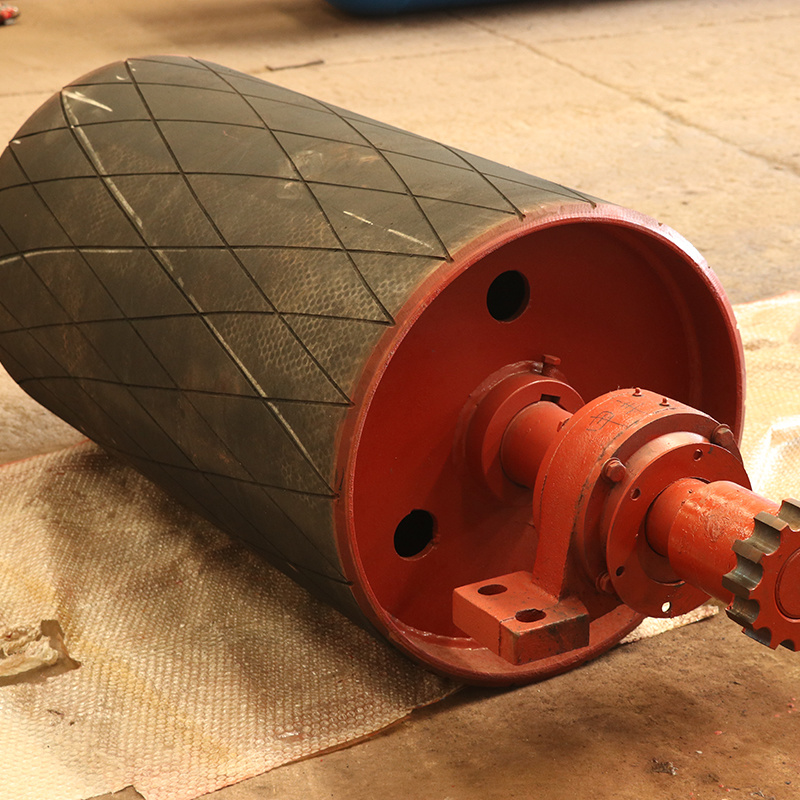

Reversing Drum

Key words:

Classification:

Product Details

The redirecting drum, also known as the guide drum or idler drum, is an indispensable key component in belt conveyor systems. Its main functions are to change the running direction of the conveyor belt, increase the wrap angle between the conveyor belt and the drive drum, or tension the conveyor belt to maintain sufficient tension.

Unlike the drive drum, the redirecting drum does not provide power; it rotates passively driven by the conveyor belt. The redirecting drums produced by Hebei Xinyuan ensure stable and efficient operation of the conveyor system with their high load capacity, flexible design, and excellent durability.

Product Introduction

The structure of the redirecting drum is similar to that of the drive drum but usually does not have rubber covering or uses a smooth rubber cover, as it mainly bears compressive and bending loads. Its main components include:

· Shell (casing): Made of high-quality carbon steel rolled and welded, with sufficient thickness and rigidity to withstand the pressure of the conveyor belt.

· Shaft: Made of high-strength alloy steel, used to support the entire drum and bear bending moments from the conveyor belt.

· Spokes (hub): The core component connecting the shell and shaft, ensuring effective transmission of force. Connection methods include welding and shrink fit.

· Bearing housing: Built-in high-quality self-aligning roller bearings ensure the drum can rotate flexibly even with slight installation errors.

Main Application Areas

The redirecting drum is widely used and is present at almost every key position of a belt conveyor:

· Tail: Acts as the return point of the conveyor belt, transitioning the belt from the return run to the carrying run.

· Head: Located just behind the drive drum, used to increase the wrap angle of the drive drum, significantly improving traction.

· Vertical tensioning device: Used as a tensioning drum, tightening the conveyor belt through vertical movement.

· In the conveyor line: Used to change the conveying direction, achieving complex conveying paths (such as Z-type or C-type elevators).

· Near loading points: Used to ensure the conveyor belt forms an ideal trough shape at the loading area.

· In front of the cleaner: Used to increase the wrap angle, improving the cleaning effect of the cleaner.

Product Design

Xinyuan redirecting drums focus on functionality, reliability, and economy in their design:

1. Structural forms:

· Single plate welding: Suitable for narrow belt widths and light load conditions.

· Double plate welding: The most commonly used structure, with good rigidity, suitable for most working conditions.

· Triple plate welding: Suitable for ultra-wide belt widths or heavy-duty drums bearing huge tension.

2. Surface treatment:

· Smooth steel surface: The most economical, suitable for most dry and non-special requirement conditions.

· Smooth rubber covering: Mainly used to prevent material sticking between the conveyor belt and drum surface (such as wet materials), reduce wear, and improve traction to some extent. It is the most commonly used rubber covering form for redirecting drums.

· Chevron/diamond rubber covering: Rarely used for redirecting drums unless auxiliary traction is needed under extremely wet and slippery special conditions.

3. Bearings and seals: High-quality self-aligning roller bearings and multiple labyrinth seals are used to effectively prevent dust and moisture ingress, ensuring the drum can operate flexibly in harsh environments and prolonging service life.

4. Functional classification design:

· 180° redirecting drum: Used at the head or tail of the conveyor.

· 90° redirecting drum: Used for vertical tensioning devices.

· ≤45° redirecting drum: Used for fine adjustment guidance within the line.

Conveyor Belt Matching Design Features

The coordination between the redirecting drum and the conveyor belt is key to ensuring its service life:

· Drum diameter: Must match the conveyor belt core type and joint method. A diameter that is too small will cause excessive bending of the conveyor belt’s carcass material (steel wire rope or fabric), leading to early fatigue damage. Generally, the drum diameter should be ≥ the minimum allowable drum diameter of the conveyor belt.

· Alignment: All redirecting drums must be installed strictly perpendicular to the conveyor centerline; otherwise, they will be a major cause of conveyor belt deviation.

· Surface flatness: The drum surface must be smooth and flat to avoid damage to the conveyor belt joints or belt surface caused by uneven welds or shell dents.

Features and Advantages

1. Precise guidance and stable operation: Accurate manufacturing and balancing ensure smooth drum rotation, effectively guiding the conveyor belt, preventing deviation, and ensuring stable system operation.

2. High rigidity and durability: Optimized structural design and high-quality materials ensure the drum can withstand huge conveyor belt tension, has strong deformation resistance, and a long service life.

3. Effectively increases wrap angle: When used as a wrap drum, it can significantly increase the wrap angle of the drive drum, enhancing the traction capacity of the entire system.

4. Flexible layout: Allows conveyor line design to break through linear limitations, achieving complex process requirements such as turning and lifting.

5. Low maintenance cost: Simple structure and low failure rate. High-quality bearings and seal design greatly extend maintenance intervals.

6. Conveyor Belt Protection: Smooth surfaces (especially rubber-coated rollers) can reduce wear on the conveyor belt, particularly protecting the joint areas.

Company Introduction

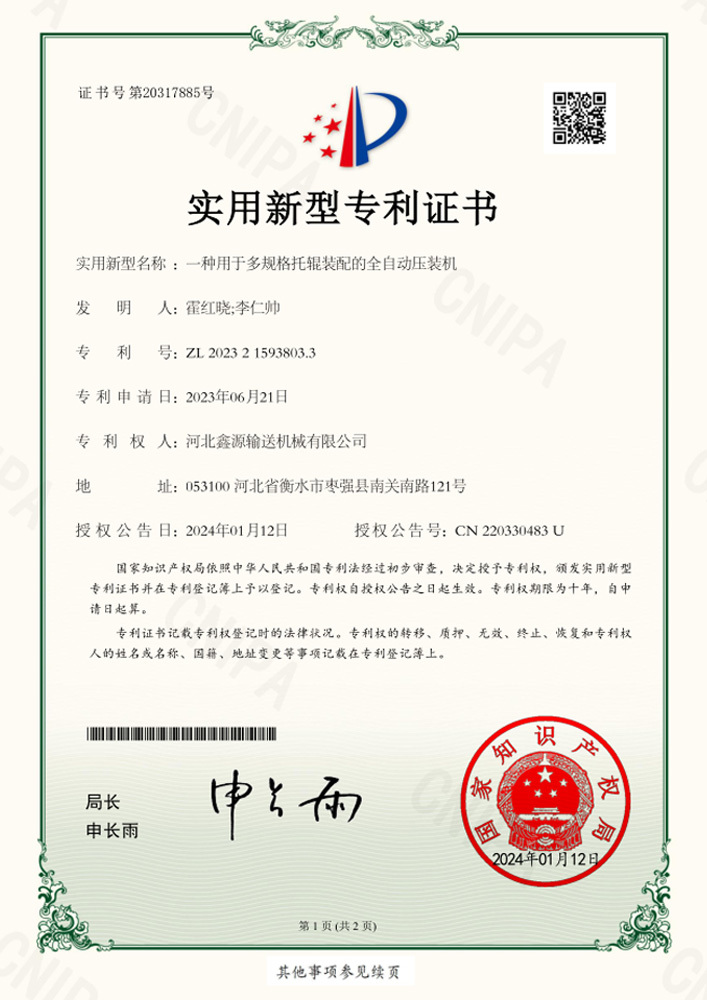

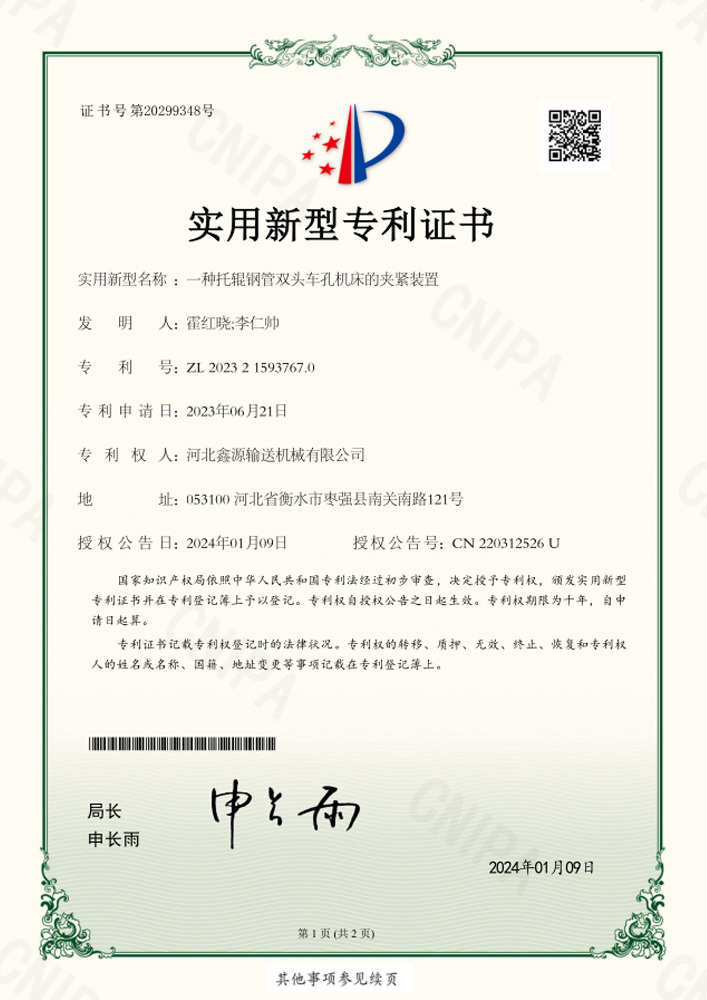

Hebei Xinyuan Conveying Machinery Co., Ltd. covers an area of 260 acres, with a large scale and 560 outstanding employees. They work together to create a brilliant performance with a 0.26 billion annual output value. The company is committed to the research and development, production and sales of belt conveyor, steel structure, glass fiber reinforced plastic and other products. The products are widely used in mining, port, electric power, chemical industry, building materials and other industries, and are deeply trusted and praised by customers.

Our advantage

The company is committed to the research and development, production and sales of belt conveyor, steel structure, glass fiber reinforced plastic and other products. The products are widely used in mining, port, electric power, chemical industry, building materials and other industries, and are deeply trusted and praised by customers.

Industry experience

Since its establishment in 2003, the company has more than 20 years of conveyor production and operation, has a professional after-sales service team, and has 18 utility model patents.

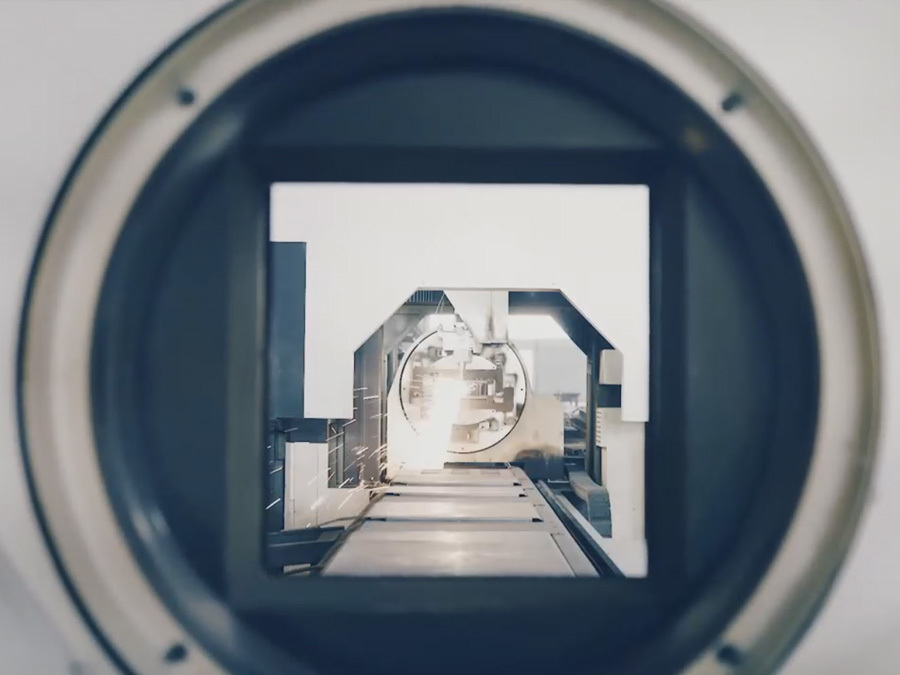

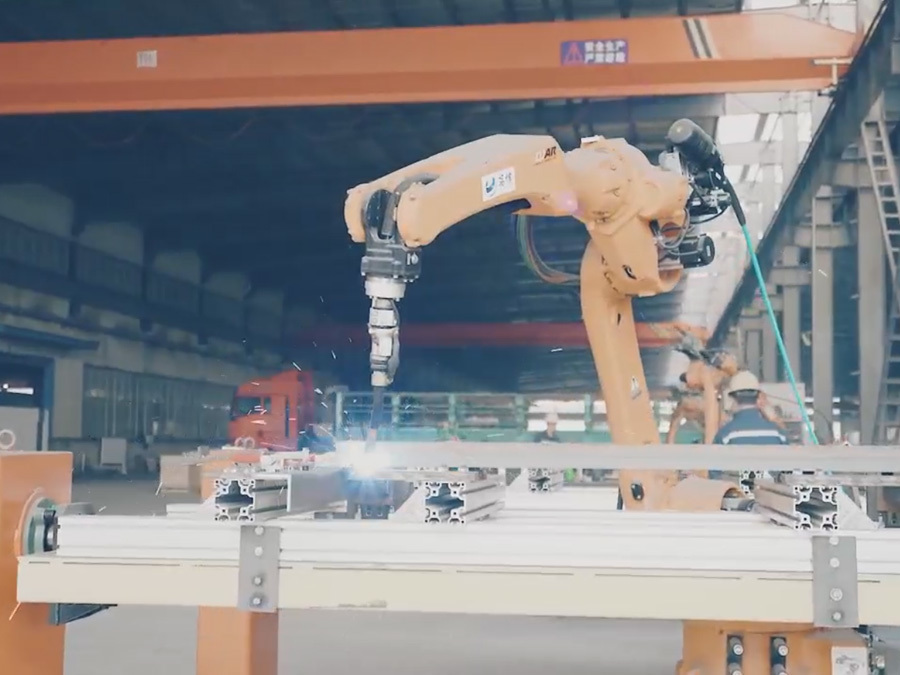

advanced equipment

The use of advanced manufacturing technology, with a variety of testing equipment, to ensure that each product is in line with national standards and customer requirements.

Marketing Network

We have established long-term and stable cooperative relations with many domestic enterprises, and exported to overseas countries and regions such as the Middle East, Central Asia and Southeast Asia.

Qualification and Exhibition

Contact Us

Hebei Xinyuan Conveying Machinery Co., Ltd.

We are dedicated to providing customers with quality products and professional services,

Welcome you to come to discuss, we are willing to work together to create a better tomorrow!

Landline:

Mobile:

Mailbox:

Address:

Company address: east side of Dongwai Ring Road, Zaoqiang County, Hengshui City, Hebei Province

Previous Page:

Next page:

Product inquiry

* Please leave your phone number and we will contact you within 24 hours!

Related Products