Classification

Contact Us

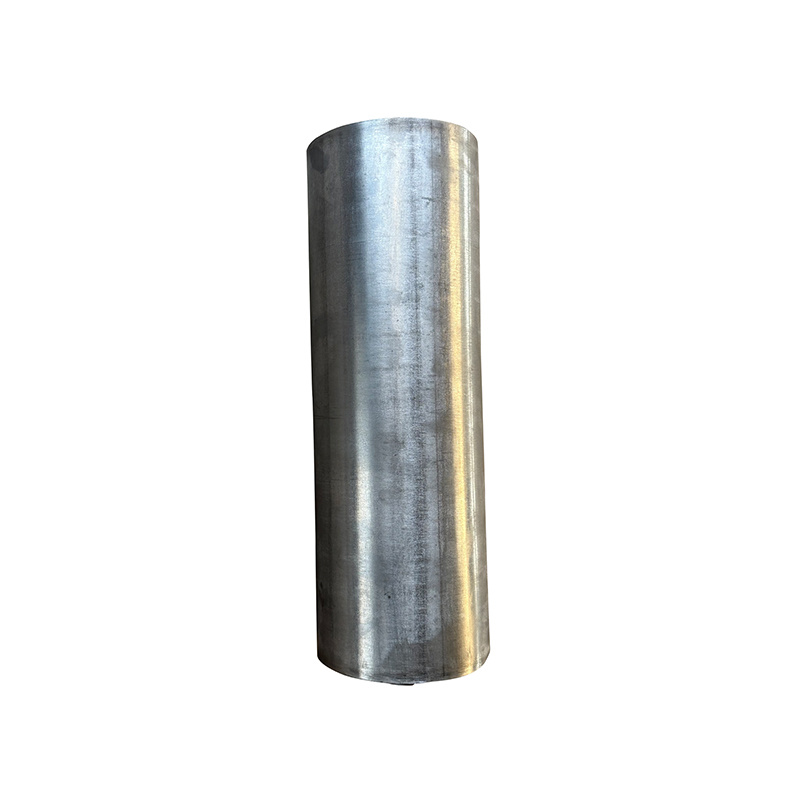

Polyurethane Transmission Roller

Key words:

Classification:

Product Details

The polyurethane drive roller is the core power component of belt conveyor systems. By connecting to the drive unit, it transmits power directly to the conveyor belt, enabling efficient material transportation. Its performance directly determines the operational efficiency and stability of the entire conveyor system. Leveraging years of expertise in conveyor machinery R&D, Hebei Xinyuan Conveying Machinery Co., Ltd. has developed high-quality polyurethane drive rollers using premium materials and precision manufacturing techniques. These rollers deliver robust driving force while offering exceptional wear resistance and corrosion protection, making them perfectly suited for the demanding, complex operating conditions across various industries.

Product Introduction

The polyurethane drive roller features a modular structural design, with its core components including the drive shaft, drum shell, spoke plates, bearing assembly, and polyurethane coating layer. The drive shaft is made from high-quality 45# alloy steel, which undergoes tempering treatment to achieve superior strength and torsional resistance, making it compatible with motors and gear reducers of varying power ratings. The drum shell is fabricated by rolling and welding high-grade Q235B carbon steel; post-welding, it undergoes full annealing to relieve internal stresses, ensuring structural stability even at high-speed operation. The spoke plates boast an optimized, non-uniform thickness design, enhanced through finite element analysis to precisely balance stress distribution, significantly boosting the roller's resistance to deformation. The bearing assembly incorporates imported, high-precision self-aligning roller bearings, paired with XinYuan's independently developed triple labyrinth sealing system—effectively preventing the ingress of dust, oil, and moisture. Most crucially, the drum shell surface is coated with a polyurethane layer using a high-pressure centrifugal casting process, achieving an adhesion strength exceeding 2.5 MPa, thereby eliminating any risk of delamination. This innovative approach not only ensures efficient power transmission but also guarantees long-lasting durability, serving as the key foundation for the product's exceptional performance and reliability.

Application Areas

· Metallurgical industry: Used in sintered ore and pellet conveyor lines at steel plants, as well as in finished steel product handling systems. These conveyors can withstand high temperatures (≤80°C), heavy loads, and abrasion from metal fragments, ensuring continuous transportation of metallurgical materials.

· Power industry: Suitable for coal transportation systems in thermal power plants and ash/slag handling conveyors, the polyurethane layer’s anti-sticking properties help minimize coal dust accumulation, while the sealed design effectively resists dust contamination from power plant environments, ensuring a stable coal supply to generating units.

· Building materials industry: In the production of cement, tiles, and other construction materials, it is used in processes such as raw material transportation and finished-product sorting. It can effectively handle the impact and abrasion caused by hard materials like sand, gravel, and cement clinker, thereby reducing equipment failure rates.

· Grain processing: Suitable for grain storage facilities and flour mills' grain conveyor systems, these food-grade polyurethane materials meet hygiene standards, featuring a smooth surface that prevents residue buildup and minimizes grain contamination and waste.

· Bulk Material Handling: In bulk cargo handling systems at terminals and stockyards—such as those for coal, ores, and fertilizers—we offer robust drive solutions tailored to accommodate large belt widths (up to 2400mm) and long-distance transportation needs.

Product Design

· Drive Structure Design: Based on differences in conveying capacity and belt width, we offer two structural options: single-drum drive and dual-drum drive. The single-drum drive is suitable for medium- to light-duty systems with belt widths ≤1200mm and conveying distances ≤100m; the dual-drum drive features a “master-slave联动” design, utilizing synchronized transmission via gears or chains, making it ideal for heavy-duty conveying systems with belt widths ≥1400mm and conveying distances exceeding 200m—this design boosts driving torque by more than 30%.

· Customized Polyurethane Layer Design: The hardness of the polyurethane layer can be tailored between Shore A85° and 95°. Shore A90° or higher is ideal for applications involving severe abrasion, while Shore A85°–90° is perfect for scenarios where protecting the conveyor belt is essential. The surface textures offer three options: plain, diamond, and herringbone patterns. The diamond pattern delivers a friction coefficient as high as 0.45, the herringbone design provides excellent bidirectional anti-slip performance, and the plain texture is specially suited for conveying materials that tend to stick easily.

· Thermal Management and Protective Design: For scenarios involving prolonged high-load operation, the interior of the cylinder shell is equipped with dedicated cooling channels, paired with aluminum alloy heat sinks to keep operating temperatures below 60°C. All metal components undergo a dual anti-corrosion treatment—phosphating followed by epoxy resin coating—ensuring salt-spray resistance for over 500 hours, making them perfectly suited for humid, highly saline environments such as ports and chemical plants.

· Precision Control Design: The drum achieves static balance accuracy of Grade G6.3 and dynamic balance accuracy of Grade G2.5, with radial runout ≤0.2mm during operation. This effectively minimizes belt misalignment and vibration, thereby extending the service life of the conveyor belt.

Features and Advantages

· Powerful driving performance: The polyurethane material boasts a friction coefficient 2.3 times higher than that of conventional steel rollers and 1.5 times greater than rubber rollers. Combined with an optimized surface texture, it significantly enhances the friction between the conveyor belt and the roller, effectively preventing slippage and achieving a driving efficiency of over 98%.

· Extra-long service life: Polyurethane material boasts wear resistance 5 to 8 times higher than natural rubber. Under the same operating conditions, it delivers a service life 2 to 3 times longer than traditional rubber-driven rollers and 4 to 6 times longer than steel rollers, significantly reducing equipment replacement costs.

· Conveyor belt protection feature: Polyurethane boasts excellent elasticity, effectively cushioning the impact forces generated during material transport and roller operation. This helps minimize stress concentration at the conveyor belt joints, reducing the risk of belt tearing and extending the belt's lifespan by more than 30%.

· Low maintenance costs: The triple labyrinth sealing design ensures the bearing achieves an IP65 protection rating, with maintenance intervals lasting over 12 months. Additionally, the polyurethane layer resists material adhesion, significantly reducing the frequency of manual cleaning—and saving up to 60 hours of maintenance labor per unit annually.

· Highly adaptable to environmental conditions: Capable of withstanding temperatures ranging from -30°C to 80°C, it exhibits excellent resistance against corrosive media such as acids, alkalis, and salts. Additionally, it features flame-retardant and antistatic properties (static dissipation time ≤ 0.1 seconds), making it suitable for use in hazardous environments like underground operations and chemical industries.

· Highly customizable: We can tailor the drum diameter (φ200mm–φ1600mm), belt width (500mm–2400mm), shaft diameter, and mounting method (flange type, shaft extension type) according to customer requirements. Additionally, we support non-standard designs for special operating conditions, ensuring personalized conveying solutions to meet your unique needs.

Company Introduction

Hebei Xinyuan Conveying Machinery Co., Ltd. covers an area of 260 acres, with a large scale and 560 outstanding employees. They work together to create a brilliant performance with a 0.26 billion annual output value. The company is committed to the research and development, production and sales of belt conveyor, steel structure, glass fiber reinforced plastic and other products. The products are widely used in mining, port, electric power, chemical industry, building materials and other industries, and are deeply trusted and praised by customers.

Our advantage

The company is committed to the research and development, production and sales of belt conveyor, steel structure, glass fiber reinforced plastic and other products. The products are widely used in mining, port, electric power, chemical industry, building materials and other industries, and are deeply trusted and praised by customers.

Industry experience

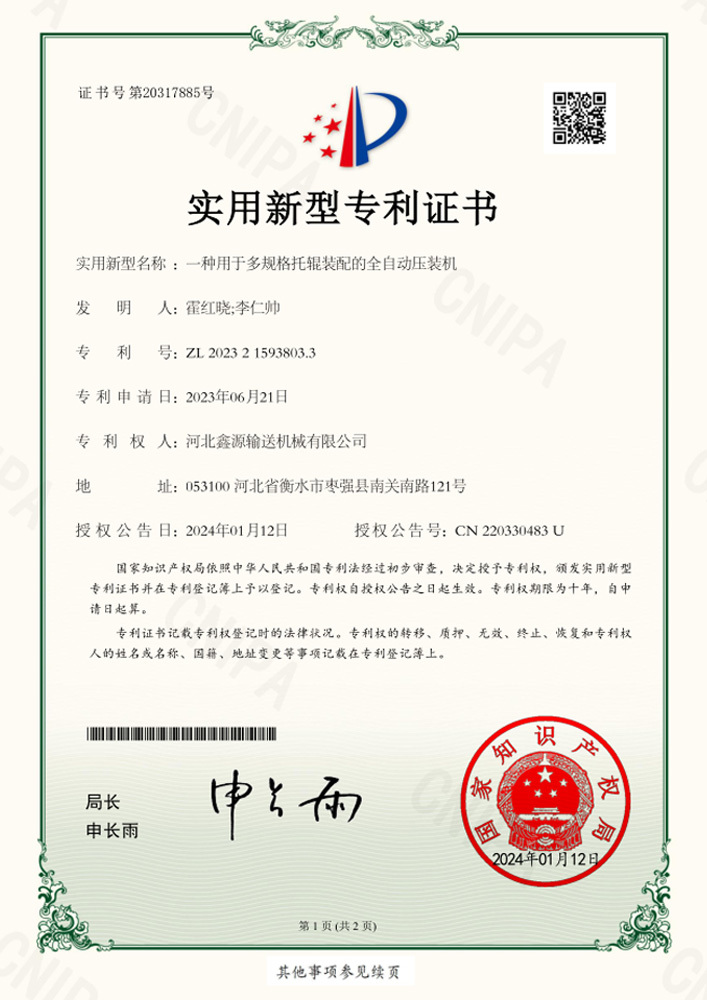

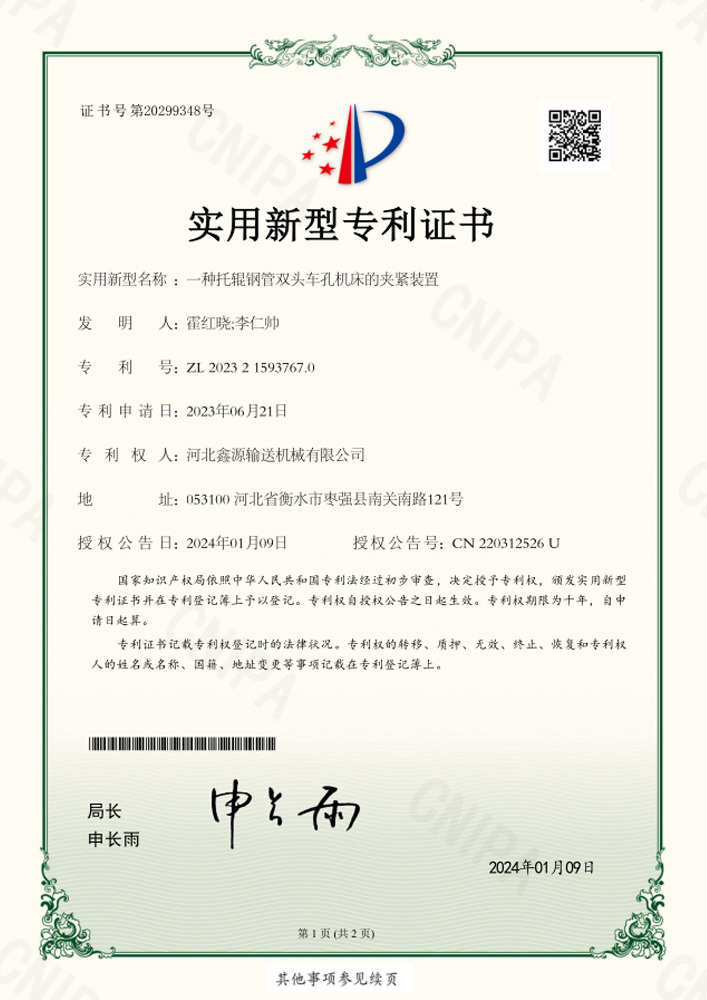

Since its establishment in 2003, the company has more than 20 years of conveyor production and operation, has a professional after-sales service team, and has 18 utility model patents.

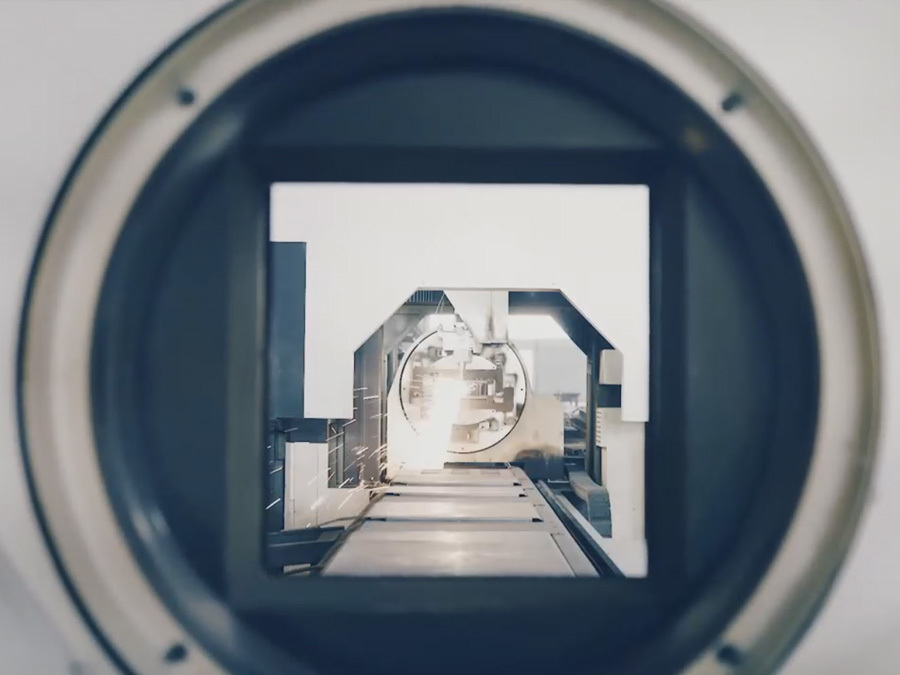

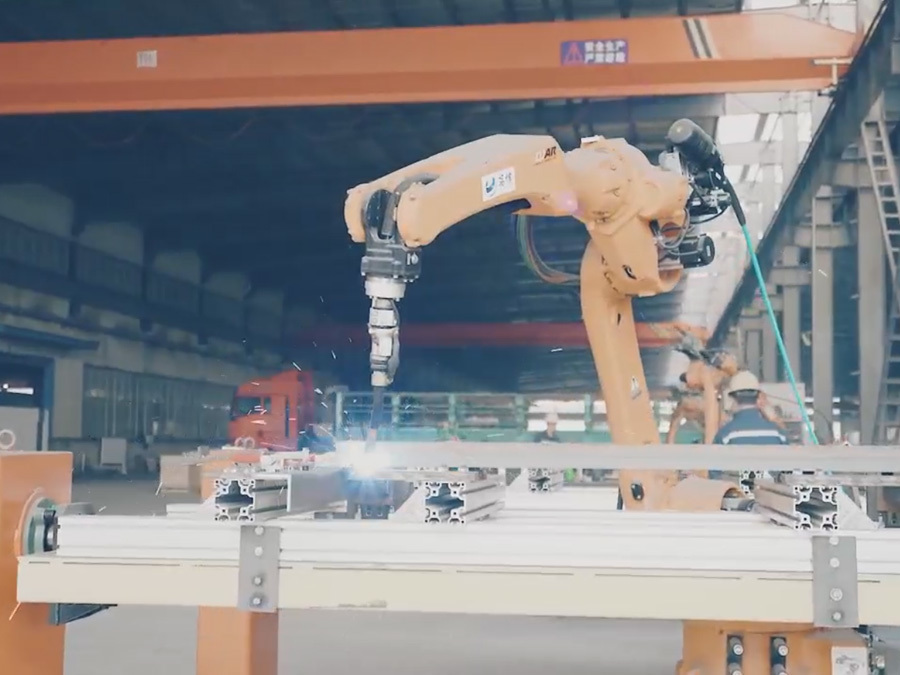

advanced equipment

The use of advanced manufacturing technology, with a variety of testing equipment, to ensure that each product is in line with national standards and customer requirements.

Marketing Network

We have established long-term and stable cooperative relations with many domestic enterprises, and exported to overseas countries and regions such as the Middle East, Central Asia and Southeast Asia.

Qualification and Exhibition

Contact Us

Hebei Xinyuan Conveying Machinery Co., Ltd.

We are dedicated to providing customers with quality products and professional services,

Welcome you to come to discuss, we are willing to work together to create a better tomorrow!

Landline:

Mobile:

Mailbox:

Address:

Company address: east side of Dongwai Ring Road, Zaoqiang County, Hengshui City, Hebei Province

Previous Page:

Next page:

Product inquiry

* Please leave your phone number and we will contact you within 24 hours!