Classification

Contact Us

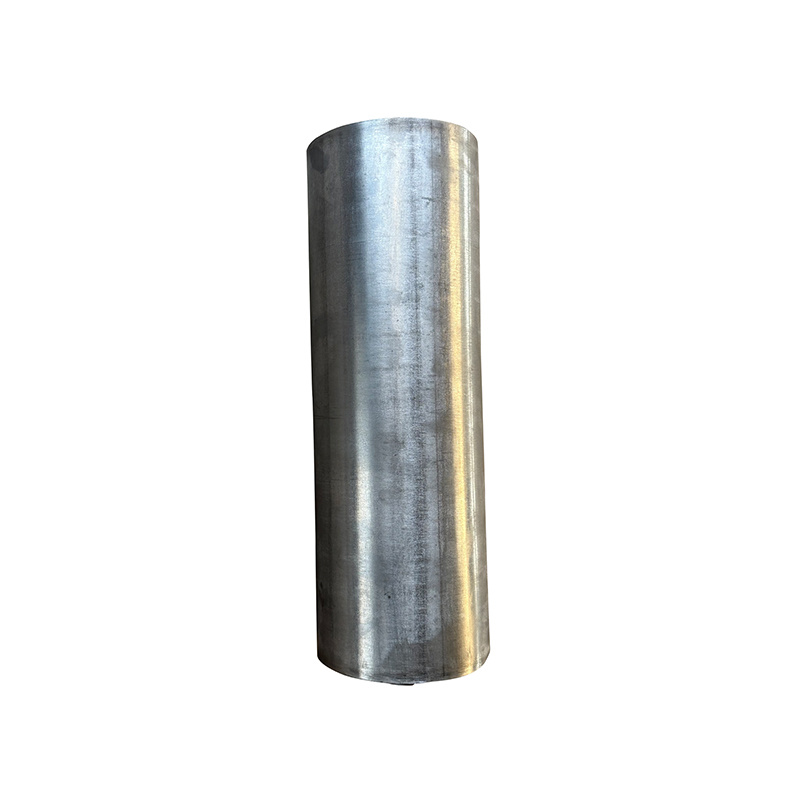

Polyurethane-idler roller

Key words:

Classification:

Product Details

The polyurethane deflection roller is a critical component in belt conveyor systems, playing an indispensable role in various material-handling applications. Hebei Xinyuan Conveyor Machinery Co., Ltd., with its advanced manufacturing processes and rigorous quality control, has developed polyurethane deflection rollers specifically designed to tackle challenging operational conditions. These rollers are engineered to ensure stable conveyor belt operation and enhance the overall efficiency of the conveying system.

Product Introduction

The polyurethane-modified idler roller is primarily composed of components such as the shell, shaft, spoke plates, and bearing housing. The shell is crafted from high-quality carbon steel, precisely rolled and welded to provide a robust, foundational structure for the roller. The shaft is made from high-strength alloy steel, offering exceptional resistance to fatigue and outstanding load-bearing capacity, ensuring stable operation even under heavy-duty conditions. Meanwhile, the spoke plates connect the shell to the shaft, optimizing force distribution and enhancing the overall rigidity of the assembly. Inside the bearing housing, top-quality self-aligning roller bearings are installed, paired with a meticulously designed sealing system that effectively prevents contaminants like dust and moisture from entering. This not only guarantees smooth, flexible roller operation but also significantly reduces maintenance frequency. Finally, the surface of the roller is coated with a carefully engineered layer of polyurethane material—this is precisely where the product’s key advantage lies.

Application Areas

· Mining operations: In coal mines, metal mines, and other extraction sites, these systems are used in underground belt conveyance, ore screening and transportation, and other critical processes. They effectively handle the heavy loads and high abrasion associated with large volumes of ore, helping to extend equipment lifespan and minimize downtime for maintenance.

· Port Logistics: Responsible for material handling tasks during cargo loading, unloading, and transshipment at ports. Whether it’s moving containerized goods or handling bulk cargo, polyurethane-guided rollers—thanks to their wear-resistant and stable properties—ensure efficient logistics operations.

· Chemical industry: Suitable for conveying chemical raw materials and finished products. Thanks to polyurethane's excellent chemical resistance, it can withstand erosion from a wide range of chemicals, ensuring reliable operation even in complex chemical environments.

· Food and Electronics: In the food and electronics industries, where hygiene standards and conveying precision are critically high, this roller effectively prevents contamination and damage to materials, ensuring accurate and smooth transportation while meeting the industry’s stringent requirements.

Product Design

· Structural Design: Employs optimized single-plate, double-plate, or triple-plate welded structures, custom-tailored to suit varying bandwidths, loads, and operating conditions. The single-plate structure is ideal for narrow bandwidth and light-load applications, offering high cost efficiency; the double-plate design serves as a versatile solution, meeting most standard conveying needs; while the triple-plate configuration is specifically engineered for heavy-duty scenarios involving ultra-wide bandwidth and high tension, delivering exceptional structural strength.

· Surface Treatment: The hardness, thickness, and surface texture of the polyurethane layer can be customized according to specific applications. High-hardness polyurethane is ideal for environments with severe abrasion, such as mining conveyor systems, while softer grades are suited for industries that demand superior protection of material surfaces. The surface can be designed with patterns like herringbone or diamond textures, significantly enhancing friction between the conveyor belt and rollers, preventing slippage, and ensuring stable material transport.

· Sealing and Protection: Equipped with multi-layer labyrinth sealing mechanisms, combined with premium-quality sealing materials, this design provides robust protection, effectively preventing dust, moisture, and other contaminants from entering the bearing area. This not only extends the service life of the bearings but also ensures continuous, stable operation of the drum even in harsh environmental conditions. Additionally, metal components undergo anti-rust treatment, further enhancing the product’s corrosion resistance.

Features and Advantages

· High wear resistance: Polyurethane material far surpasses ordinary rubber in abrasion resistance, effectively withstanding the impact and friction of materials, significantly extending the service life of rollers and reducing equipment replacement costs—particularly ideal for applications involving high-abrasion conditions.

· Excellent anti-stick properties: The polyurethane surface resists material adhesion, minimizing residue and buildup, thereby reducing the risk of conveyor belt misalignment and ensuring a clean, efficient conveying process while cutting down on cleaning and maintenance efforts.

· Excellent buffering performance: Effectively absorbs impact forces and vibrations generated during conveyor belt operation, reducing equipment noise while protecting the conveyor belt and other conveying components, thereby enhancing system stability and reliability.

· High Load Capacity: Combining optimized structural design with premium materials, it boasts exceptional load-bearing capability, easily meeting the demands of heavy-duty conveying applications while maintaining stable operation under high-load conditions—without deformation or damage.

· Precise Guidance: Featuring high manufacturing precision, it provides accurate guidance to the conveyor belt during operation, effectively preventing belt misalignment and ensuring the safe, stable performance of the conveying system—ultimately boosting production efficiency.

· Highly adaptable: Customized solutions can be tailored to meet the specific requirements of different industries and operating conditions, including dimensions, structure, surface treatments, and more—ensuring versatile performance and making it suitable for a wide range of conveying applications.

Company Introduction

Hebei Xinyuan Conveying Machinery Co., Ltd. covers an area of 260 acres, with a large scale and 560 outstanding employees. They work together to create a brilliant performance with a 0.26 billion annual output value. The company is committed to the research and development, production and sales of belt conveyor, steel structure, glass fiber reinforced plastic and other products. The products are widely used in mining, port, electric power, chemical industry, building materials and other industries, and are deeply trusted and praised by customers.

Our advantage

The company is committed to the research and development, production and sales of belt conveyor, steel structure, glass fiber reinforced plastic and other products. The products are widely used in mining, port, electric power, chemical industry, building materials and other industries, and are deeply trusted and praised by customers.

Industry experience

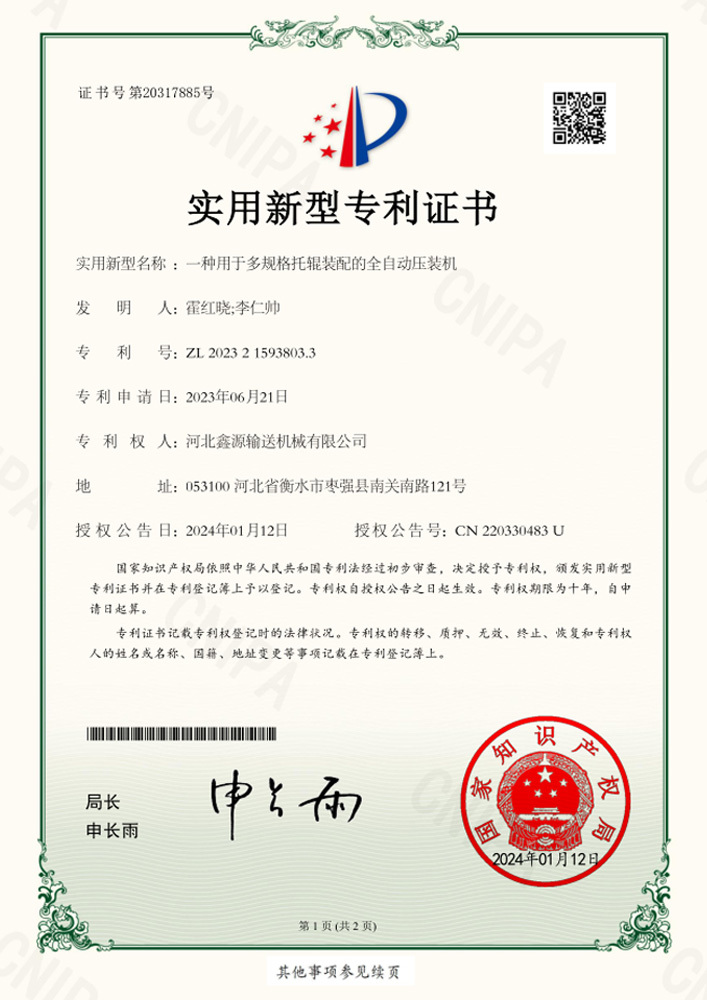

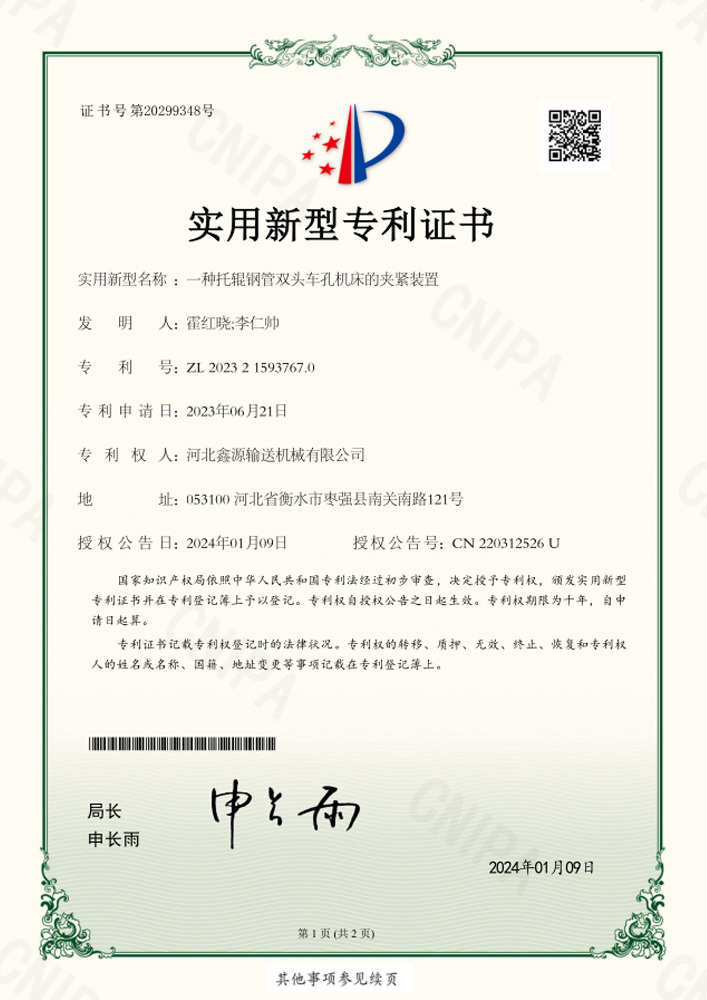

Since its establishment in 2003, the company has more than 20 years of conveyor production and operation, has a professional after-sales service team, and has 18 utility model patents.

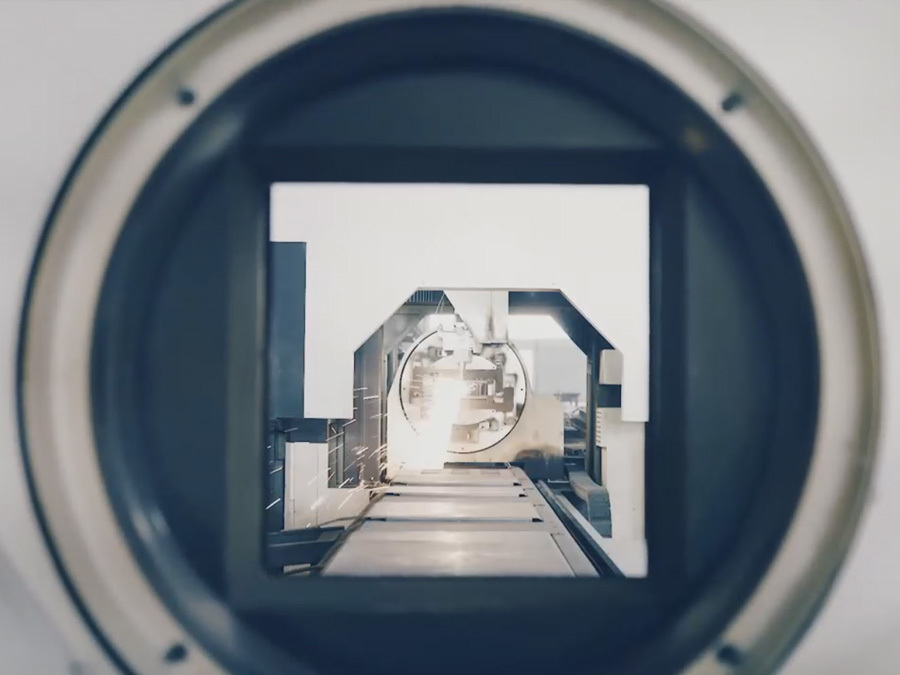

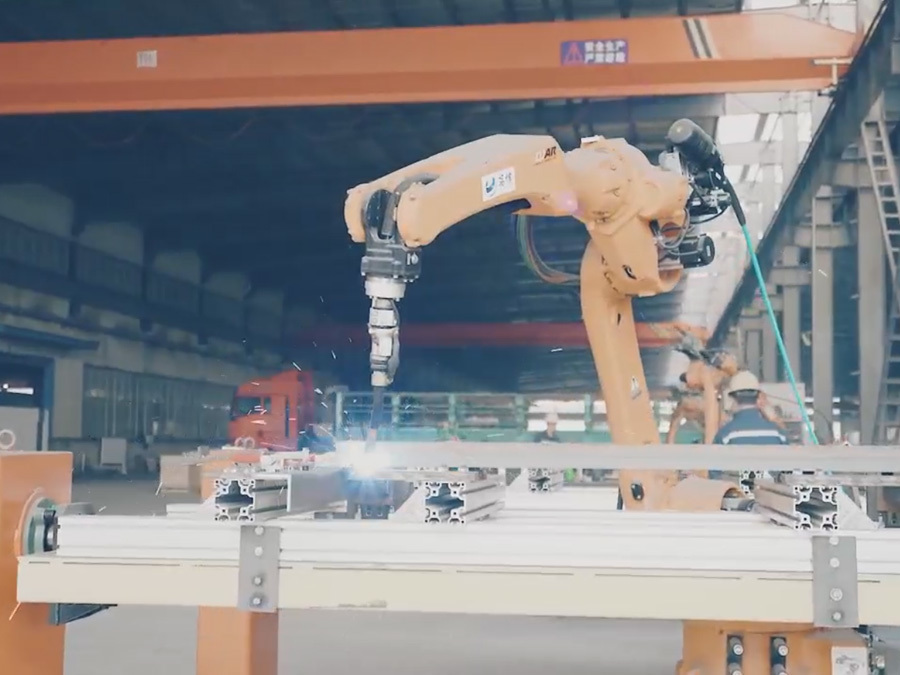

advanced equipment

The use of advanced manufacturing technology, with a variety of testing equipment, to ensure that each product is in line with national standards and customer requirements.

Marketing Network

We have established long-term and stable cooperative relations with many domestic enterprises, and exported to overseas countries and regions such as the Middle East, Central Asia and Southeast Asia.

Qualification and Exhibition

Contact Us

Hebei Xinyuan Conveying Machinery Co., Ltd.

We are dedicated to providing customers with quality products and professional services,

Welcome you to come to discuss, we are willing to work together to create a better tomorrow!

Landline:

Mobile:

Mailbox:

Address:

Company address: east side of Dongwai Ring Road, Zaoqiang County, Hengshui City, Hebei Province

Previous Page:

Next page:

Product inquiry

* Please leave your phone number and we will contact you within 24 hours!